What are bio-plastics?

On Awaji Island, the beautiful green hills surrounding villages and towns are known in Japanese as “Satoyama”. Some of the most impressive Satoyama scenery appears in Spring when cherry blossoms are in full bloom. These cherry blossoms are a special type named Yamasakura. However, this lovely spring scenery with Yamasakura is now threatened by an overgrowth of bamboo. Bamboo grows easily in many places, not only in Awaji. To protect Satoyama scenery from bamboo overgrowth, the groves are cut down and used for fuel, charcoal and also to make several craft products. The unchecked growth of not only bamboo but many other plants also cause social and environmental issues.

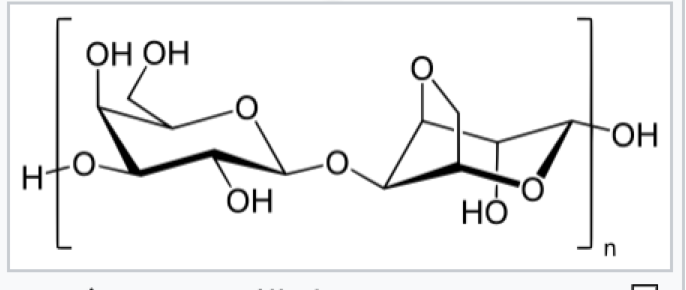

However, needless to say, plants, especially green ones including several types of crops, produce starches and various polysaccharides from carbon dioxide mixed with energy from sunlight that serve as an energy source for humanity. Such plant products are called bio-mass in general. Starch is a polymer of glucose, one type of polysaccharide. Besides starch, plants have another type of polysaccharide called cellulose that protects and strengthens their own cells. Cotton, long used as clothing material, is a form of cellulose that protects cotton seeds. Another familiar example of plant polysaccharide is agar, a polymer of galactose. Since humans lack appropriate enzymes to digest agar, we enjoy its texture rather than its nutritional value.

Recently, we have started to reconsider the value of plants as bio-mass in light of environmental issues brought about by green-house effects. Plastics, the essential petroleum-based materials used in every walk of life, could be replaced by materials made from bio-mass (named bio-plastics). This trend may help to reduce the green-house effect since bio-mass is originally made from CO2 and, unlike petrochemical plastics, even the burning of biomass fuels, does not lead to a net increase in CO2. Some bio-plastics are also biodegradable. This feature is another difference between biomass and petrochemical plastics. Let’s take a closer look at the new trend of bio-plastics in the world.

One definition of “plastic” is a material which can change shape as desire through heat and pressure. They are made by polymerization of petrochemicals such as ethylene, propylene, and styrene. Since no microorganism has enzymes that can digest these polymers, plastics accumulate on the earth if not incinerated. The problem is obvious when we clean the sea shore of Awaji Island (Sea pollution by micro-plastics in the world, H. Takada, in Japanese Circulation of resources (2018) 29, p261). You may not see many plastics at first, but a closer look at the sand reveals very small plastic pieces called micro-plastics. In the sea, fish eat these micro-plastics and as we eat the fish, microplastics eventually enter bodies where they are a potential cause of cancer. Therefore, micro-plastic pollution is one of the most serious environmental issues for us today.

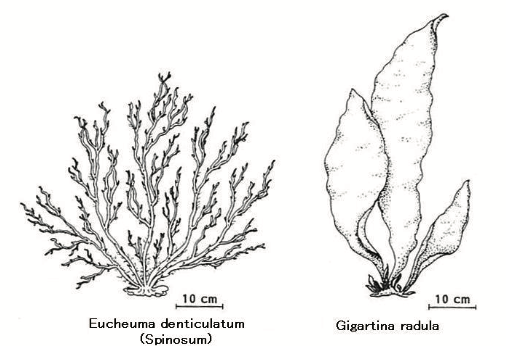

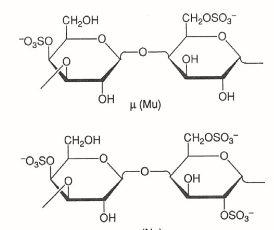

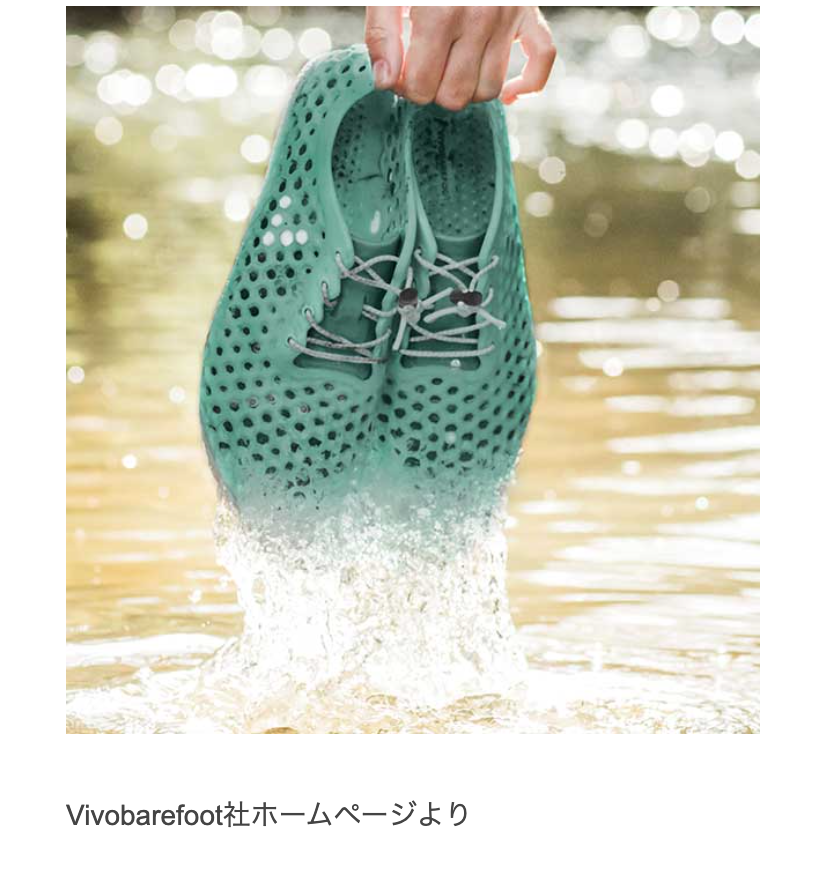

During the last 10 years many new businesses have opened that use bioplastics to avoid the environmental risks caused by micro-plastics. One new idea are polysaccharides made of Karagenin from red algae and Alginic acid from brown algae like Japanese sea weed Konbu (Kelp). These materials can be extracted by heating and/or alkaline treatment, then used as substitutes for plastics due to their malleability and physical strength. The British corporation Loliare (https://notpla.com) produces a water cup made of Algenic acid. This cup is used to serve water to marathon runners. After drinking the water, the runners can eat the cup to avoid creating trash. Shoes (https://vivobarefoot.com) and skis (https://WDNR-alpine.com) are also made of bio-plastics from Karagenin, originally found in algae produced in Ireland (Property and application of Carragenan, Y. Hayashi in Japanese, Seni-Gakkaishi (2009) 65, p412). Karagenin has been used for a long time to make milk based foods of either soft and/or hard texture. A Japanese corporation Kimica is producing many of these materials from Karagenin and was awarded by the Japanese government for their contribution to SDGs (https://kimica.jp/corporates/).

Besides bio-plastic from sea algae, poly-lactic acids are another important resource for bio-plastics like textiles and shopping bags. Lactic acids are made by fermenting the starch of some crops, mainly maize. Since materials from poly-lactic acid are biodegradable, presenting one possible solution to the environmental issue of climate change. However, as the global population grows, we face a world-wide food shortage that may force us to reevaluate the value of materials such as poly-lactic acid bioplastics.